Product description:

Ordyl SY 300 is a solvent type permanent dry film for special MEMS applications. The Ordyl SY 300 in connection with his auxiliary product line CFC free: Ordyl SY Developer and Ordyl SY Rinse, offer the following performances:

- Excellent resolution

- Excellent heat resistance

- Excellent chemical resistance

- High stability

- Biocompatibility

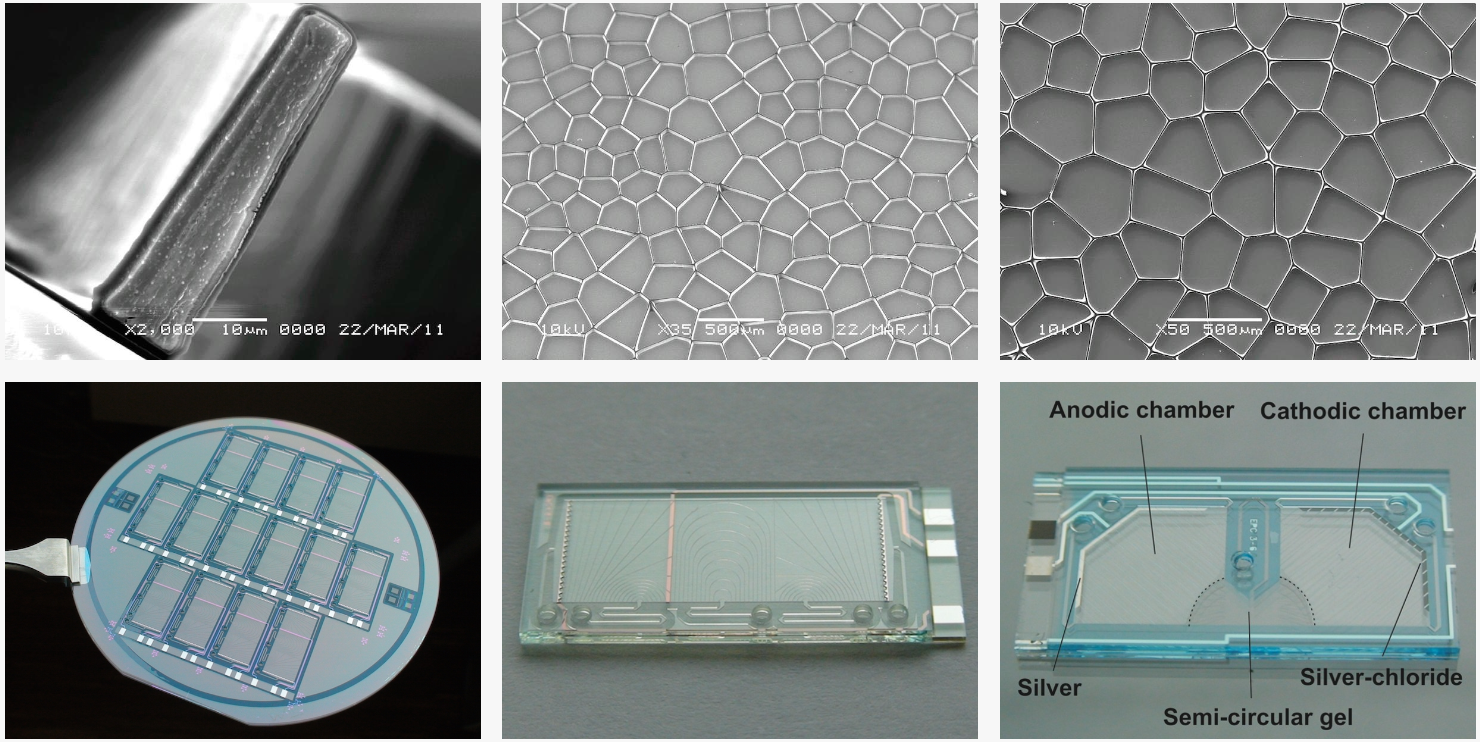

Ordyl SY 300 could be used for sealing application, due to the capability to be pressed together with a top plate.

1. MAIN FEATURES

- Excellent Chemical Resistance

- Biocompatibility

2. TYPICAL APPLICATION

- MEMS

- Sealing application

3. AVAILABLE THICKNESS

- 10 µm (0.4 mils)

- 20 µm (0.8 mils)

- 30 µm (1.2 mils)

- 55 µm (2.2 mils)

- 90 µm (3.6 mils)

- 125 µm (5.0 mils)

- Different thickness available on request

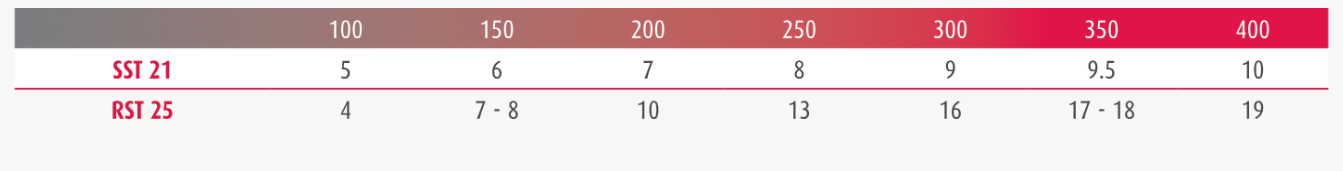

4. EXPOSURE

5. HOLD TIME AFTER EXPOSURE

We recommend a mínimum hold time after exposure of at least 15 minutes

6. DEVELOPING

SY 300 could be developed with spray, paddle or dipping method.

Using Ordyl SY Developer in dipping process at room temperature, maintain the Break Point between 60% and 80%, depending on the application. Use Ordyl SY Rinse to remove scum and clean the surface.

If final rinse with DI water is necessary, an intermediate rinse with IPA is suggested.

7. POST-BAKE

A Post-Baking is necessary after developing (150ºC for 30-60 min)

8. STRIPPING

Ordyl SY 300 can be stripped only before post-bake

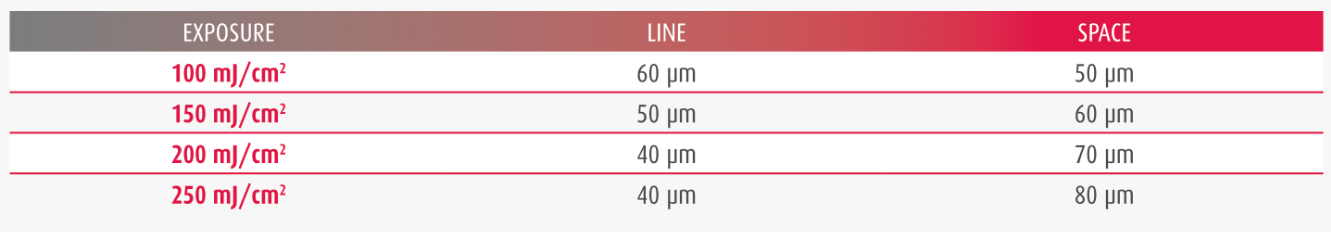

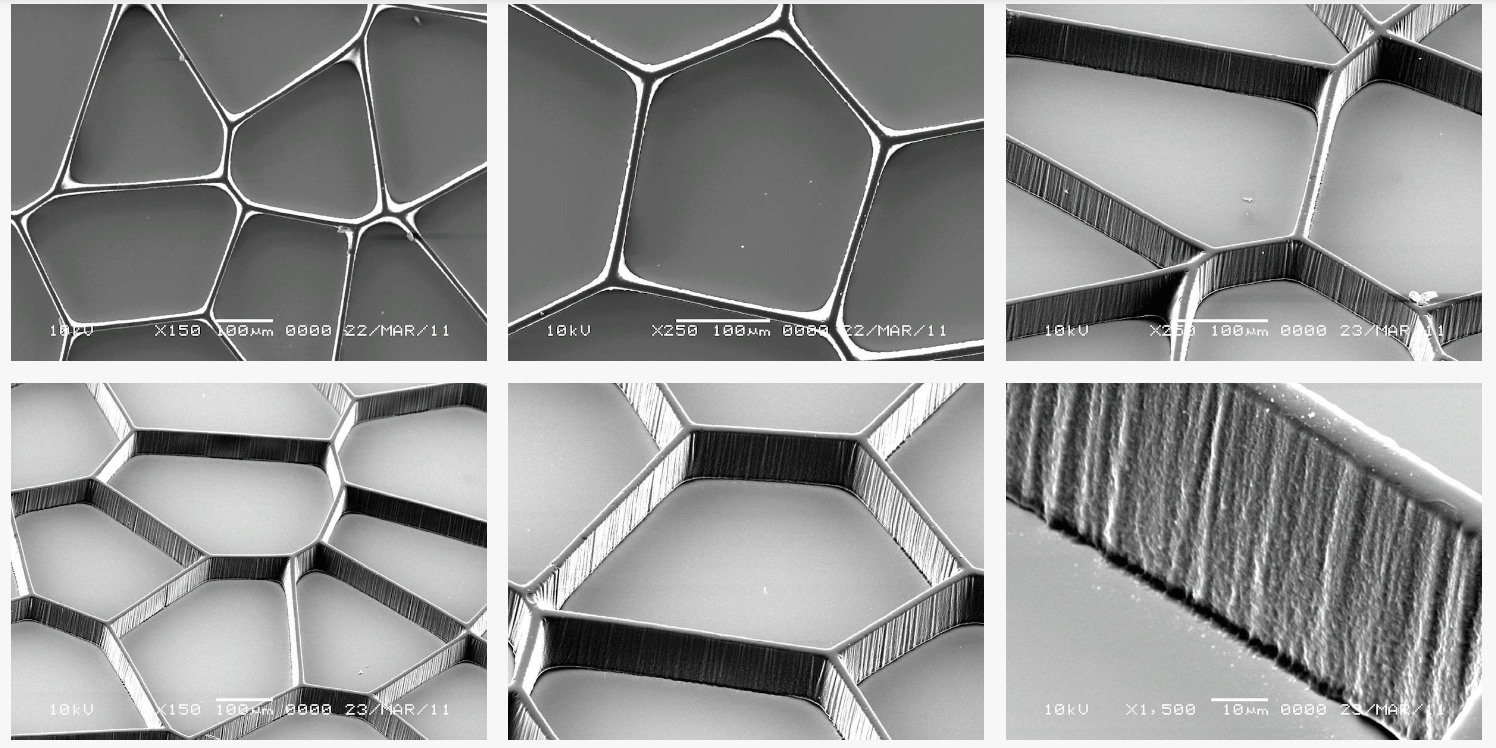

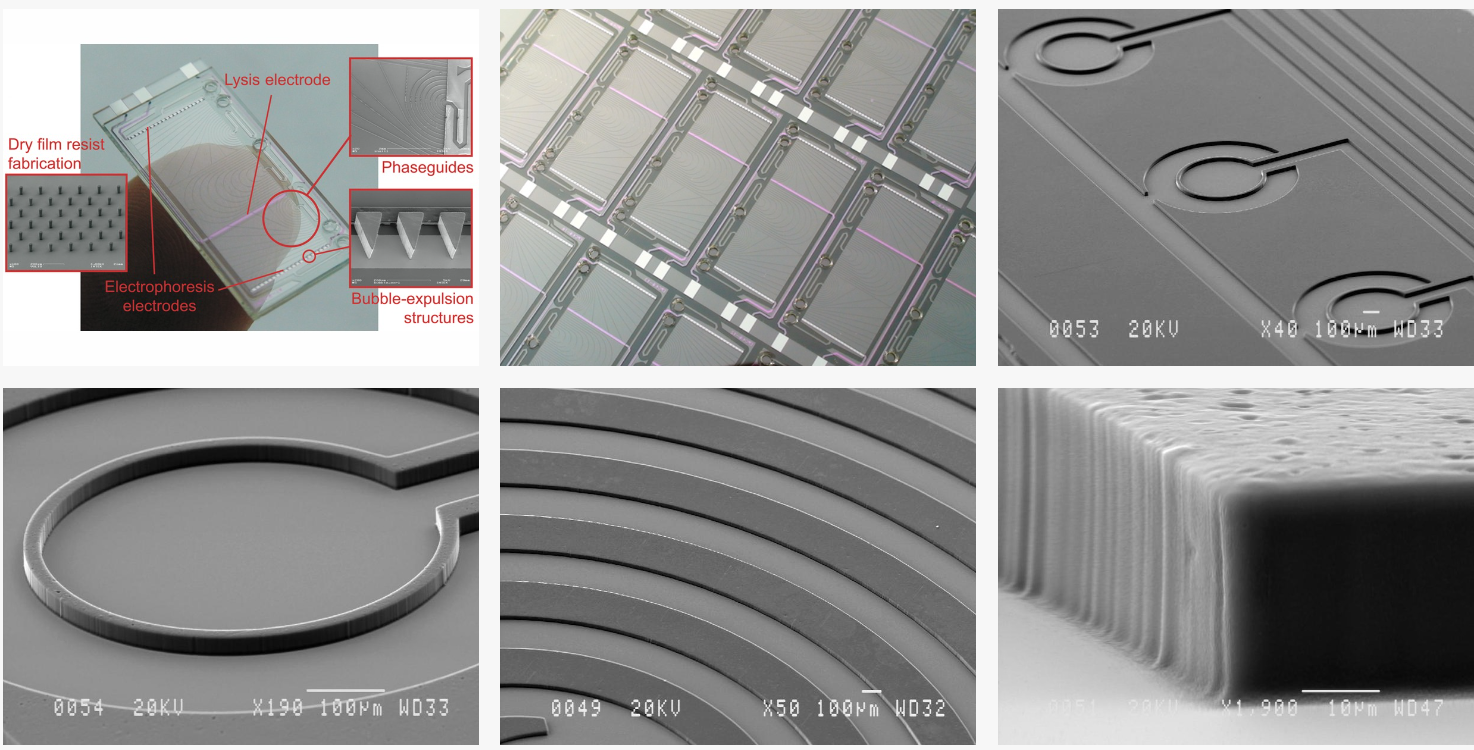

9. RESIST PROFILE

For the test we used a 55 µm thickness dry film, laminated on SiO2 wafer.

GALLERY

Nuestro equipo técnico y comercial está a su disposición para cualquier consulta sobre la gama Ordyl SY 300.